Dr. Ing. Hutschenreuther, Weimar

Road Construction project on B27, north of Marbach; driving in the direction of Eschwege

Lattice inlays S & P Carbophalt G were placed locally at Road Construction B27 north of Marbach, driving in the direction Eschwege by S & P Reinforcement GmbH on 22nd September 2003.

Dr. Hutschenreuther Engineering Company for structure testing Ltd. were engaged to extract asphalt cores within the area of the above-mentioned road works, jointly in the attendance of the ASV Fulda and S & P Reinforcement Ltd. These core samples required to be tested in accordance with the Course Interlocking according to Leutner (conforming with ALP A-StB, T4, Edition 1999).

Testing of the Layer Interlocking according to Leutner:

In the testing of the Layer Interlocking according to Leutner, a core is split to pieces by means of a shearing appliance integrated into the top Marshall-press on the corresponding asphalt layers. The core is fixed and then pressure is loaded at the layer delimitation by the shearing jaws at a constant rate of feed. The shear force is determined into the dependence of the shear distance in the shear plane (layer delimitation limit).

The maximum of the shear force indicates the failure load at which the layer interlocking can bring forces only wanting to lessen to the motion of the shearing jaws between the two courses. The maximum shear force and the belonging shear distance are recorded in a force/distance diagram. The shear distance is the movement of the shearing jaws, which is in load direction measured and corrected [1] at this achieving the maximum shearing force.

Darmstadt (dissertation Stöckert) does a revision by extensive research to the above mentioned requests and the following values were the suggested:

In compliance with the regulations and in accordance with the valid ZTV Asphalt StB or ZTVT StB, with regard to the asphalt characteristics (degree of compaction and void content) and at the attention of the necessary laying conditions; a high layer interlocking can be obtained.

shear-force

- layer delimitation surface-/ binder course: min 25 kN

- layer delimitation binder-/ base course: min 20 kN

- layer delimitation surface -/ base course: min 16 kN

For the shear distance no requirement was formulated. With the help of the shear distance it is possible to describe the way of the curve, and therefore a conclusion concerning a failed behaviour. An acceptable failed behavior arises in the context of the ranges mentioned following for the shear distance:

shear-distance

- layer delimitation surface-/ binder course: 2.0 — 4.0 mm

- layer delimitation binder-/ base course: 1.5 — 3.0 mm

- layer delimitation surface -/ base course: 1.0 — 3.0 mm [1]

Results:

For this evaluation, only the results of cores n 2 – 7 were recorded. The shear plane of core n 1 laid beside the layer delimitation. All cores became sheared at the layer delimitation base course – binder course.

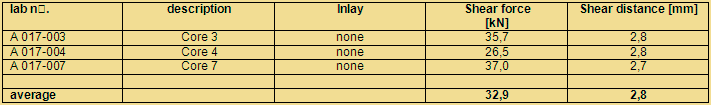

Cores without inlays:

The average value (shear force) lies with 32.9 KN, the average shear distance at 2.8 mm. All experimental values were adhered to or surpassed at the average values and as well at the individual values. It meant a much better layer interlocking is that between the asphalt base course and the asphalt binder course.

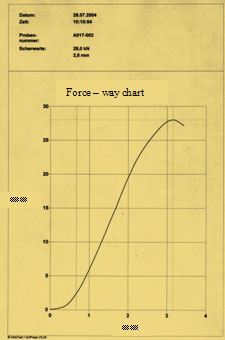

Figure 1 shows force-distance-diagram of core n 4. This course can be judged to be absolutely typical.

figure4: force-way – chart, corse n 4

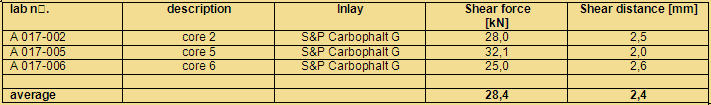

Cores with S&P Carbophalt G Inlays:

The average value (shear force) is at 28.4 KN, the average shear distance at 2.4 mm. All experimental values were adhered to or surpassed at the average values and as well at the individual values. It meant a much better layer interlocking is that despite inlay between the asphalt base course and the asphalt binder course. The inlay S & P Carbophalt G according to the shear parameters sticks together with the asphalt base course and with the asphalt binder course well. The relationship between the cores without inlay and cores with S & P Carbophalt G averages to 0.86. This means, it becomes that despite the lattice inlay, a layer interlocking of 86%in comparison with the core without inlay (28.4 KN : 32.9 KN = 86%).

So the experimental value of 80% is achieved effortlessly here.